Quick Answer: Ultrasonic cleaners use high-frequency sound waves in a liquid to create microscopic bubbles that scrub away dirt and grime. The magic happens through a process called cavitation, which is incredibly effective for cleaning delicate and intricate items.

The Sonic Secret Behind Spotless Surfaces

At first glance, an ultrasonic cleaner just looks like a metal tank filled with liquid. But inside, powerful science is at work. These devices use high-frequency sound waves—often tens of thousands of vibrations per second—to attack dirt in a way brushes and cloths simply can’t. The waves pass through the cleaning solution, triggering the formation and collapse of millions of microscopic bubbles.

Because ultrasonic energy evenly fills the tank, every reachable part of an object’s surface gets consistent scrubbing—perfect for tight spaces like jewelry clasps, precision instruments, and laboratory tools.

How Cavitation Does the Heavy Lifting

The real cleaning hero inside an ultrasonic bath is the cavitation process. Cavitation occurs when the ultrasonic waves create alternating high- and low-pressure cycles in the liquid:

- Low-pressure phase: Microscopic voids—tiny bubbles—form in the cleaning fluid.

- High-pressure phase: The bubbles collapse violently, releasing shockwaves and bursts of heat.

- Scrubbing effect: This bubble implosion acts like miniature brushes, loosening and carrying away dirt, grease, and residues.

It’s a bit like having billions of tiny invisible scrubbers working simultaneously, even in the finest cracks and crevices.

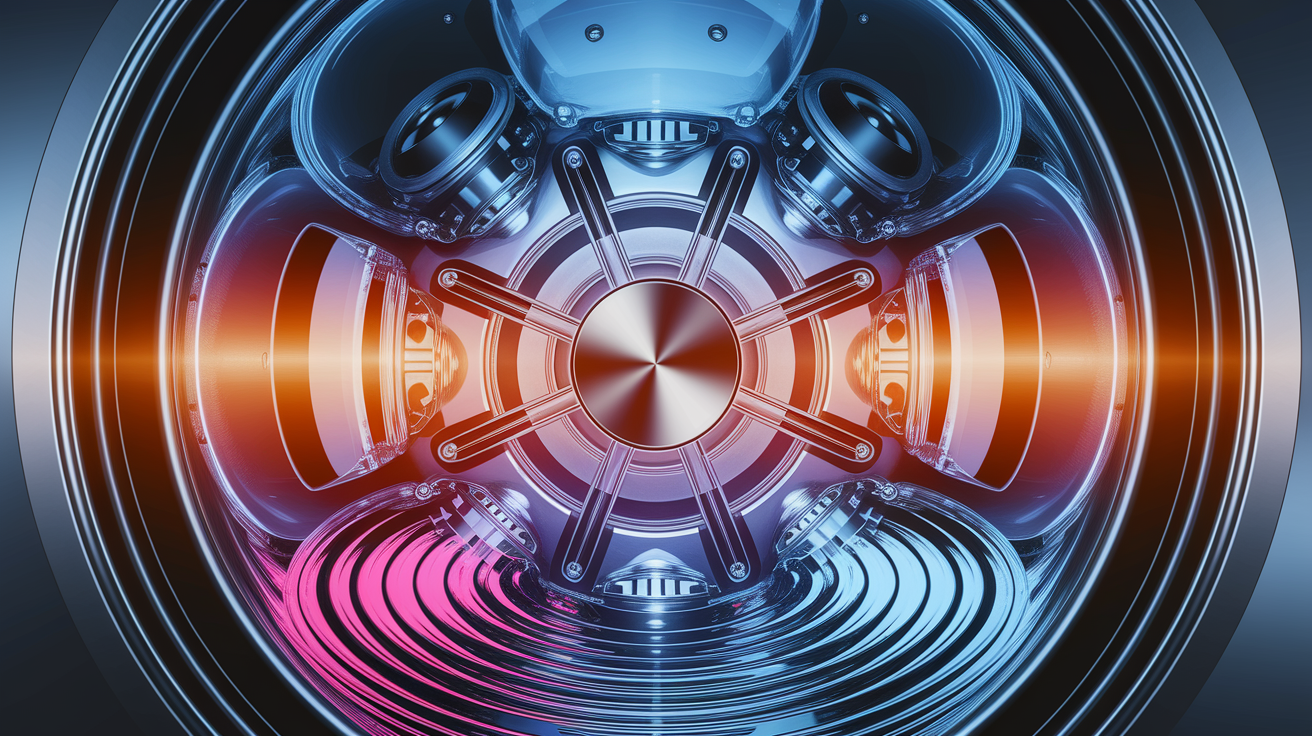

Inside an Ultrasonic Cleaner: Core Components

An ultrasonic cleaner relies on several key parts working together:

- Tank: Usually stainless steel and designed to hold the cleaning solution safely during operation.

- Generator: Produces the high-frequency electrical signals needed for ultrasonic cleaning.

- Transducer: Converts electrical signals into mechanical vibrations. Many are made of piezoelectric materials like lead zirconate titanate (PZT), which slightly change shape when voltage is applied.

- Heating element (optional): Warms the cleaning fluid to improve cleaning performance.

Together, these components create ultrasonic waves that travel through the liquid, ensuring full coverage during the cleaning cycle.

Fine-Tuning: Factors That Affect Cleaning Performance

Several parameters determine how effective an ultrasonic cleaner will be:

- Frequency: Lower frequencies (~25 kHz) produce larger, more powerful bubbles for tough contamination; higher frequencies (80–120 kHz) create gentler, smaller bubbles for delicate parts.

- Temperature: Warm solutions often speed up the cleaning process and help break down stubborn residues.

- Solution type: The right cleaning chemical can drastically improve results, depending on the item and contaminant.

- Power settings: More ultrasonic energy can boost cleaning speed, but needs to be balanced for sensitive surfaces.

Even degassing—removing dissolved gases from the solution—can increase cleaning power by improving cavitation efficiency.

Best Applications for Ultrasonic Cleaning

Thanks to their precision and thoroughness, ultrasonic cleaners are used across many fields:

- Jewelry: Restoring shine to rings, chains, and gemstones.

- Medical instruments: Cleaning surgical tools before sterilization.

- Electronics: Removing flux and debris from circuit boards.

- Automotive: Cleaning carburetors and fuel injectors.

- Laboratories: Preparing equipment for sensitive experiments.

In each case, ultrasonic technology provides a non-abrasive method to achieve thorough cleaning, even in areas invisible to the naked eye.

Riding the Waves to Pristine Results

Ultrasonic cleaners harness the energy of sound to do the work most cleaning tools can only dream of. By combining cavitation bubbles, precise control of frequency and temperature, and the right cleaning chemistry, they deliver fast, thorough, and safe results for a huge variety of items.

So the next time you see an ultrasonic bath in action, remember—you’re watching the power of invisible waves wage a microscopic cleaning battle, leaving surfaces spotless and ready for their next task.