Quick Answer: Peltier devices are clever solid-state heat pumps that use electricity to move heat from one side to another, creating a hot side and a cold side. They work silently, have no moving parts, and can both heat and cool simply by reversing the current flow.

Heat Moves in Silence: Introduction to Peltier Devices

Imagine being able to chill or warm something without noisy fans, compressors, or refrigerants. That’s exactly what a Peltier device does! Also called thermoelectric coolers (TECs), these small modules quietly shuttle heat using the Peltier effect. With just an electrical current, heat flows from one side to the other, allowing precise temperature control in a compact, solid-state package.

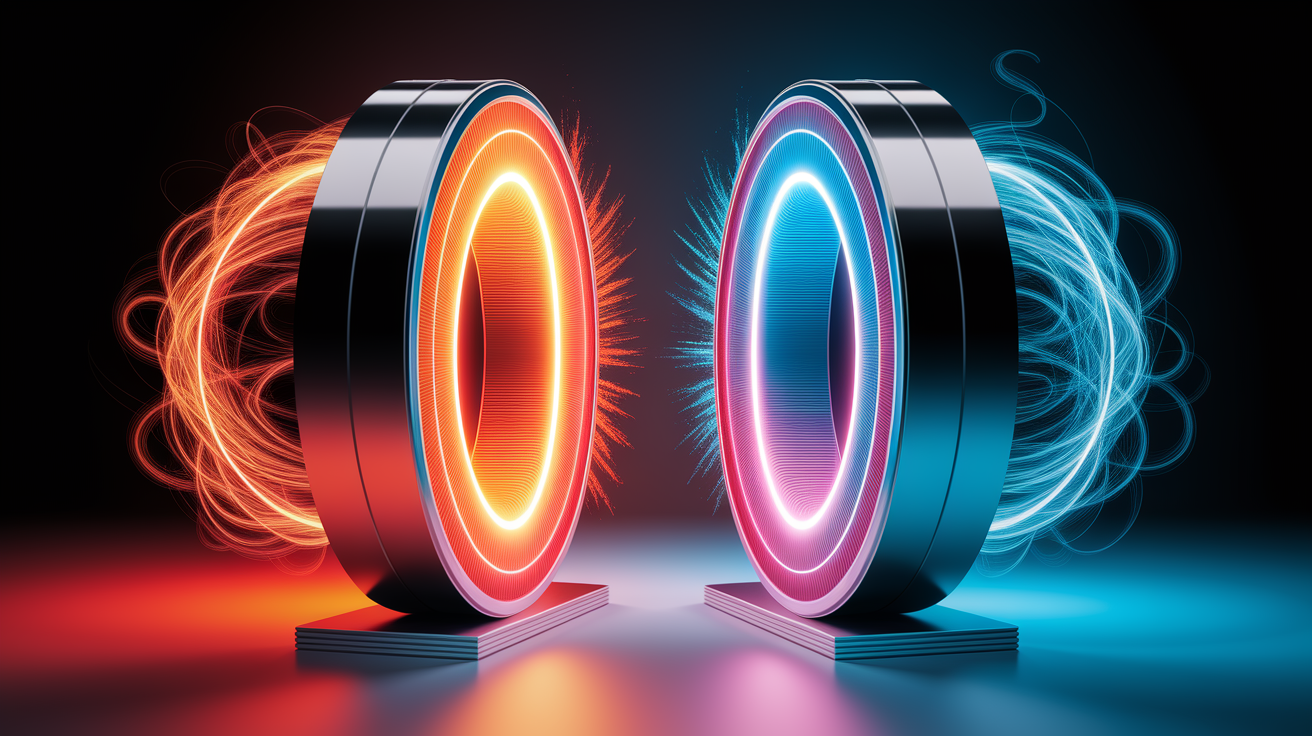

The Peltier Effect Explained

The Peltier effect is a phenomenon where heat is absorbed or released at the junction between two different conductors or semiconductors when an electrical current passes through. Here’s the neat part: the direction of current decides which side gets cold and which gets hot. Reverse the current, and the hot and cold sides swap instantly. No moving parts, no mechanical wear—just pure thermoelectric magic at work.

Alongside the Seebeck effect, which generates electricity from a temperature difference, and the Thomson effect, where heating or cooling happens along a conductor in a temperature gradient, the Peltier effect is one of the three main thermoelectric effects. But for cooling and heating, Peltier is the star of the show.

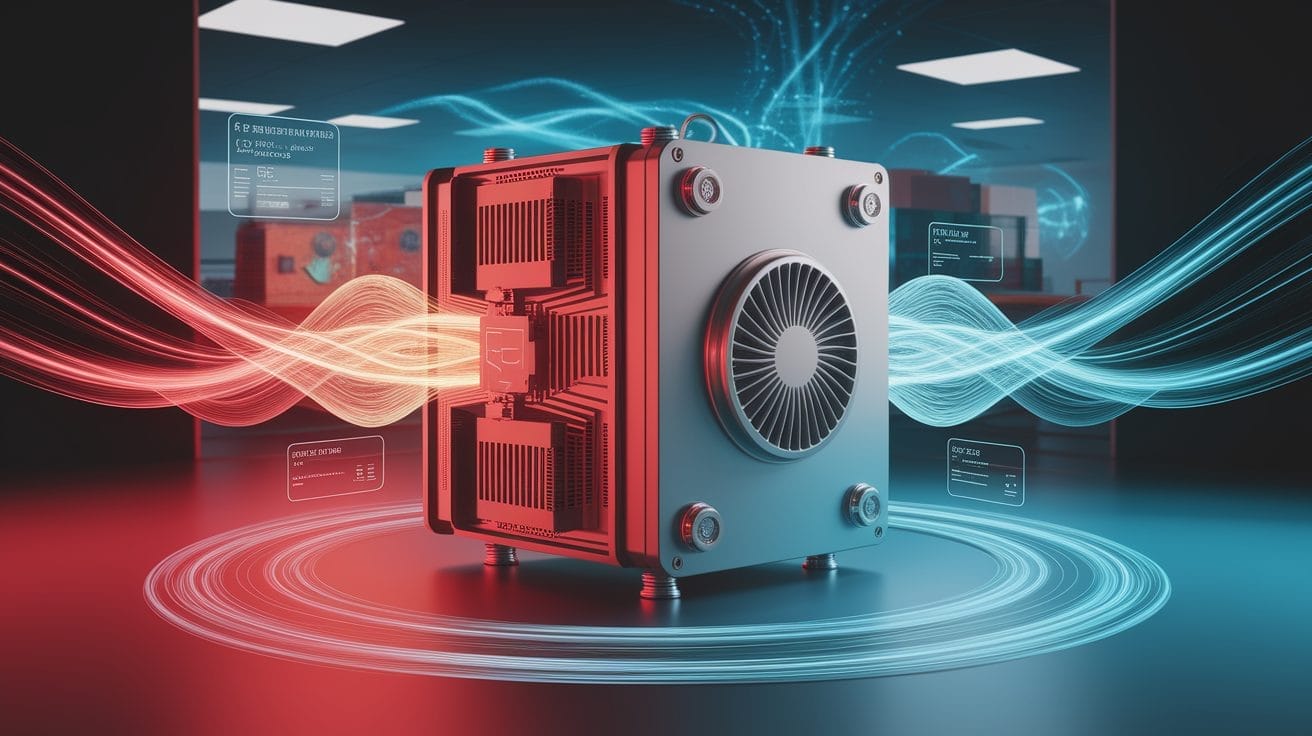

Inside a Peltier Module: Structure and Components

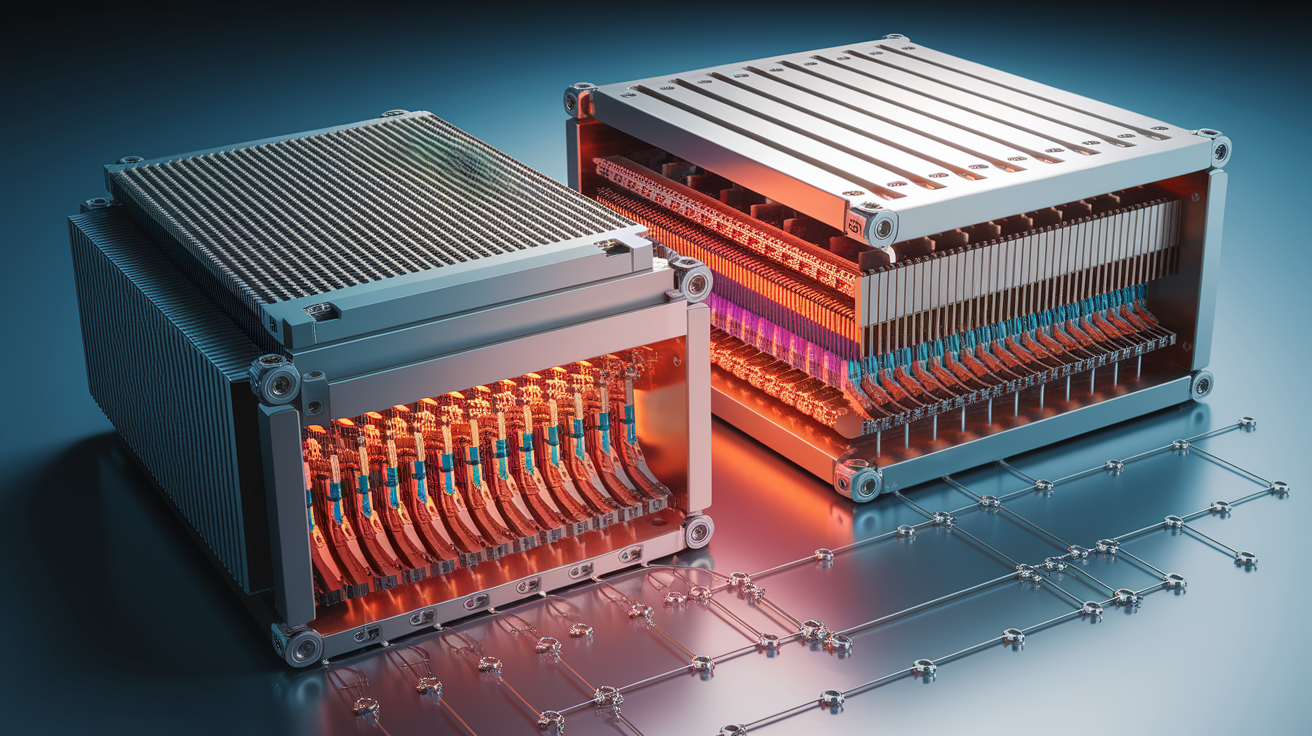

A typical peltier module is like a microscopic heat pump sandwich:

- Semiconductor pairs: Tiny cubes or pillars of p-type and n-type materials, often bismuth telluride.

- Electrical series, thermal parallel: The pairs are arranged so that electrons in the n-type and “holes” in the p-type both carry heat in the same direction.

- Ceramic plates: These form the outer layers, providing electrical insulation while letting heat pass through efficiently.

- Copper conductors: Bonded inside to help transfer heat from the semiconductors to external heat sinks.

The result: a solid-state heat transfer engine, compact enough to mount directly onto a processor or inside a portable cooling box.

Electric Current and Heat Flow: Making Cooling Happen

Here’s how these modules operate in action:

- Apply a DC electrical current to the module.

- Electrons move through n-type semiconductors, while holes move through p-type ones.

- This movement of charge carriers drags heat from one ceramic surface to the other.

- One side becomes cold as it absorbs heat, the other hot as it releases heat.

- Reverse the current, and the roles swap!

This is thermoelectric cooling in a nutshell—solid state refrigeration with no motors or fluids to worry about.

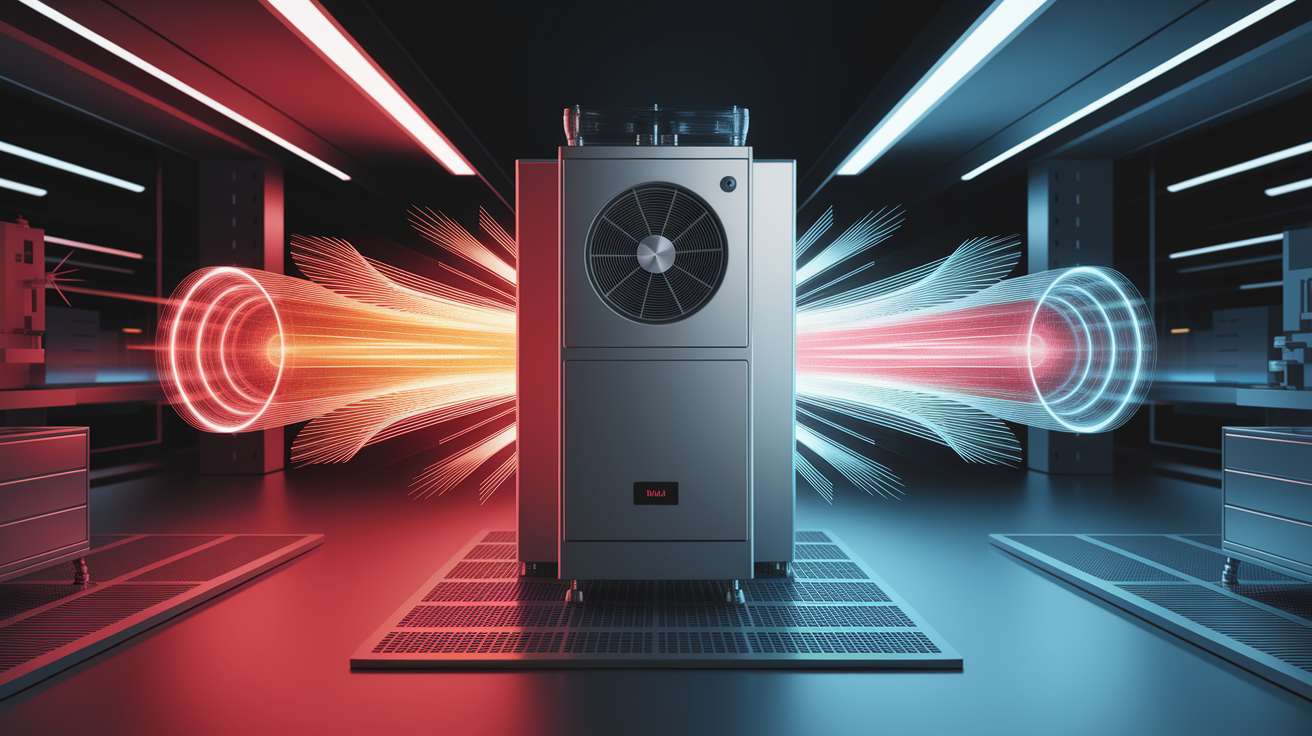

Performance Metrics: What Limits a Peltier Device?

Peltier devices are remarkable, but they do have boundaries. According to research, performance depends on:

- Heat sink efficiency: If the hot side can’t release heat effectively, the cold side will warm up fast.

- Ambient temperature: Warmer surroundings make it harder to maintain large temperature differences.

- Module design: Dimensions, material quality, and internal resistance affect cooling capacity.

- Thermal leakage: Heat can sneak back from hot to cold through the device materials.

Most single-stage modules can achieve a maximum temperature difference of around 70°C between the sides—but only with excellent heat dissipation. Waste heat from electrical resistance also chips away at their efficiency, so careful thermal management is key.

Practical Uses and Design Tips

Peltier devices find homes in many applications, from keeping electronics cool to acting as mini heat pumps in portable refrigerators. As noted in manufacturer guides and engineering blogs, they shine when:

- Precise temperature control is required.

- Silence or lack of vibration is important (no moving parts).

- Space is limited, but heating/cooling is needed.

Design Tips for Best Results

- Always use a high-quality heat sink, possibly with a fan or water cooling, on the hot side.

- Ensure flat, well-joined contact surfaces with thermal paste for minimal thermal resistance.

- Control power input to avoid overheating or wasting energy.

- Consider multi-stage modules if you need larger temperature drops.

Closing the Circuit: Key Takeaways on Peltier Devices

Peltier devices are a fascinating, practical embodiment of the thermoelectric effect in action. They can quietly pump heat, switch between cooling and heating, and operate in compact spots where traditional refrigeration won’t fit. While their efficiency can’t match that of compressor-based systems, their solid-state reliability and versatility make them a favorite in many niche applications.

Whether you’re designing a lab instrument, a cooler for your camping trip, or simply curious about solid state cooling technology, the magic of the Peltier effect puts precise thermal control right at your fingertips—no moving parts attached.