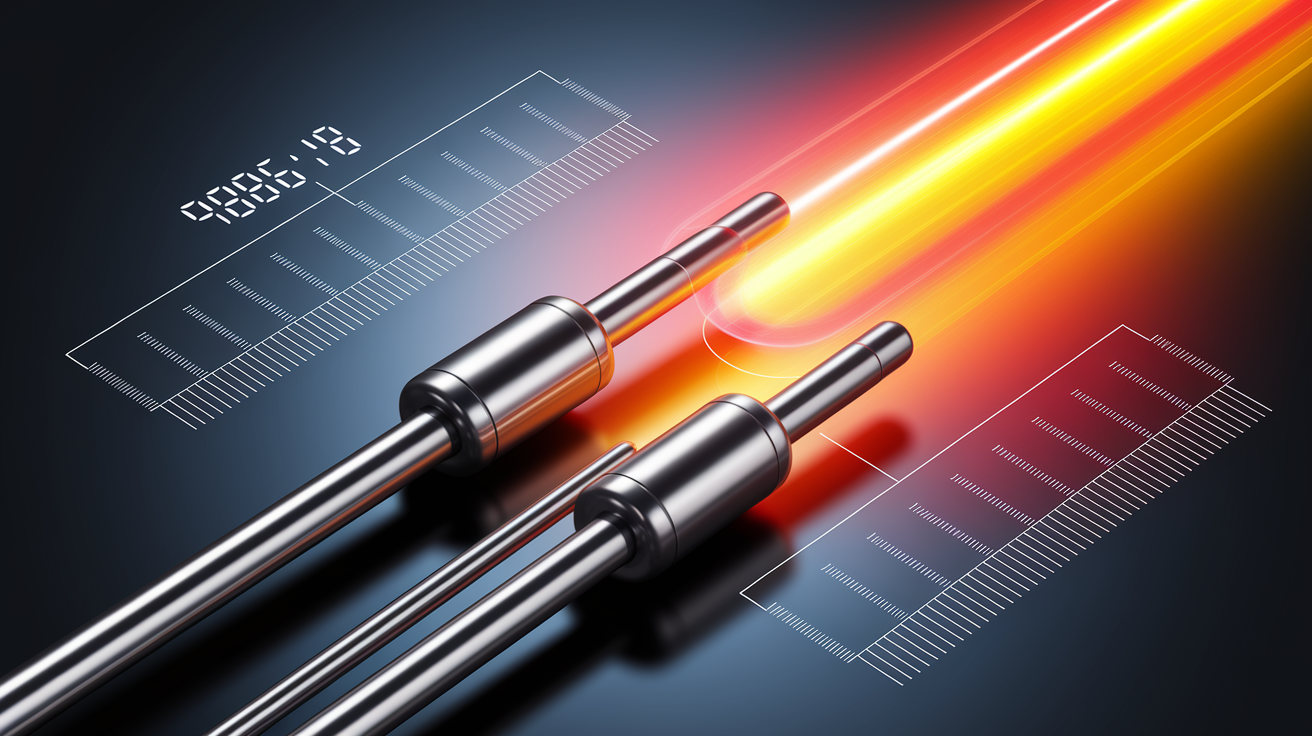

Quick Answer: Thermocouples are rugged temperature sensors that work by generating a voltage when two different metals meet at different temperatures. They’re inexpensive, fast-responding, and can measure everything from icy cryogenic levels to blazing furnace heat.

Igniting Your Thermocouple Temperature Journey

Thermocouples are among the most widely used temperature sensors in industry, science, and everyday appliances. They’re small, self-powered, and reliable – the go-to for measuring temperature in places where other sensors might fail. Whether it’s inside a jet engine, deep in a chemical reactor, or in your kitchen oven, these devices can keep tabs on heat with impressive accuracy.

How Thermocouples Measure Temperature

The magic behind a thermocouple lies in the Seebeck effect. Here’s the simplified picture: Take two different metal wires, join them at one end (the “hot junction”), and leave the other ends separate (the “cold” or reference junction). When there’s a temperature difference between these ends, an electrical voltage forms. That voltage is tiny — often just microvolts — but it changes predictably with temperature.

- The hot junction is placed where you want to measure temperature.

- The cold junction is kept at a known or measured temperature.

- Electronics measure the voltage, apply cold junction compensation, and convert it to a temperature reading.

This direct conversion of heat into electricity without a battery or supply power is what makes a thermocouple an active transducer in temperature measurement.

Popular Thermocouple Types and Temperature Ranges

Not all thermocouples are created equal. The materials used for the two wires set the limits for temperature range, stability, and cost.

- Type K (Nickel-Chromium/Nickel-Alumel): General purpose, –200°C to ~1260°C, affordable and durable.

- Type T (Copper/Constantan): Good for low temperature sensing down to –200°C, high accuracy in cryogenics.

- Type J (Iron/Constantan): Limited to ~750°C, works well in vacuum and reducing atmospheres.

- Type S & R (Platinum-Rhodium alloys): Very high temperature capability up to ~1600°C, used in furnaces and laboratories.

The choice depends on the temperature range you need, the environmental conditions, and the desired sensor accuracy.

Choosing the Right Thermocouple for Your Application

If you’re wondering how to choose the right thermocouple type, start by considering:

- Temperature range: Know your process’s minimum and maximum temperatures.

- Environment: Will it face vibration, moisture, corrosive gases, or high pressure?

- Accuracy: For critical science or industrial control, higher accuracy types may be worth the cost.

- Response time: Fine wires react faster; thicker wires survive longer.

- Compatibility: Ensure your readout or temperature transmitter supports the thermocouple type.

When comparing thermocouples vs RTDs, remember that RTDs (like platinum resistance thermometers) offer better accuracy in moderate temperatures, but thermocouples excel in extreme heat or rugged conditions.

Best Practices for Installation and Accurate Measurements

To get reliable readings:

- Use proper insulation and sheathing (like stainless steel or Inconel) for harsh environments.

- Minimize electrical noise by using shielded cables and proper grounding.

- Place the sensing tip where the process temperature is most representative.

- Perform regular temperature calibration to avoid drift over time.

- In high-vibration settings, use thermowells or spring-loaded fittings for stability.

Advantages and Limitations of Thermocouples

Advantages

- Wide measurement range — from cryogenic to over 2000°C (type-dependent).

- Extremely rugged and vibration resistant.

- Fast response time for temperature changes.

- Low cost and simple construction.

- Self-powered, no external electricity required for sensing.

Limitations

- Lower accuracy compared to RTDs or thermistors in narrow ranges.

- Signal susceptible to electrical noise and drift over time.

- Requires cold junction compensation for precise readings.

- Limited lifespan in very high temperatures or corrosive atmospheres.

Wrapping Up Your Thermocouple Temperature Insights

Thermocouples are truly workhorse industrial sensors, capable of tackling almost any temperature monitoring challenge. They combine durability, wide range, and low cost in a way few other sensors can match. By understanding the Seebeck effect, matching the type to your needs, and following best installation practices, you can harness precise and dependable heat measurements across countless applications. Whether for blazing furnaces, icy storage, or dynamic industrial processes, thermocouples keep working quietly, turning heat into data — one tiny voltage at a time.