Quick Answer: Thermoelectric generators turn heat directly into electricity using the fascinating Seebeck effect. With no moving parts, they transform temperature differences into reliable power for everything from spacecraft to portable devices.

Igniting the Heat-to-Electricity Magic

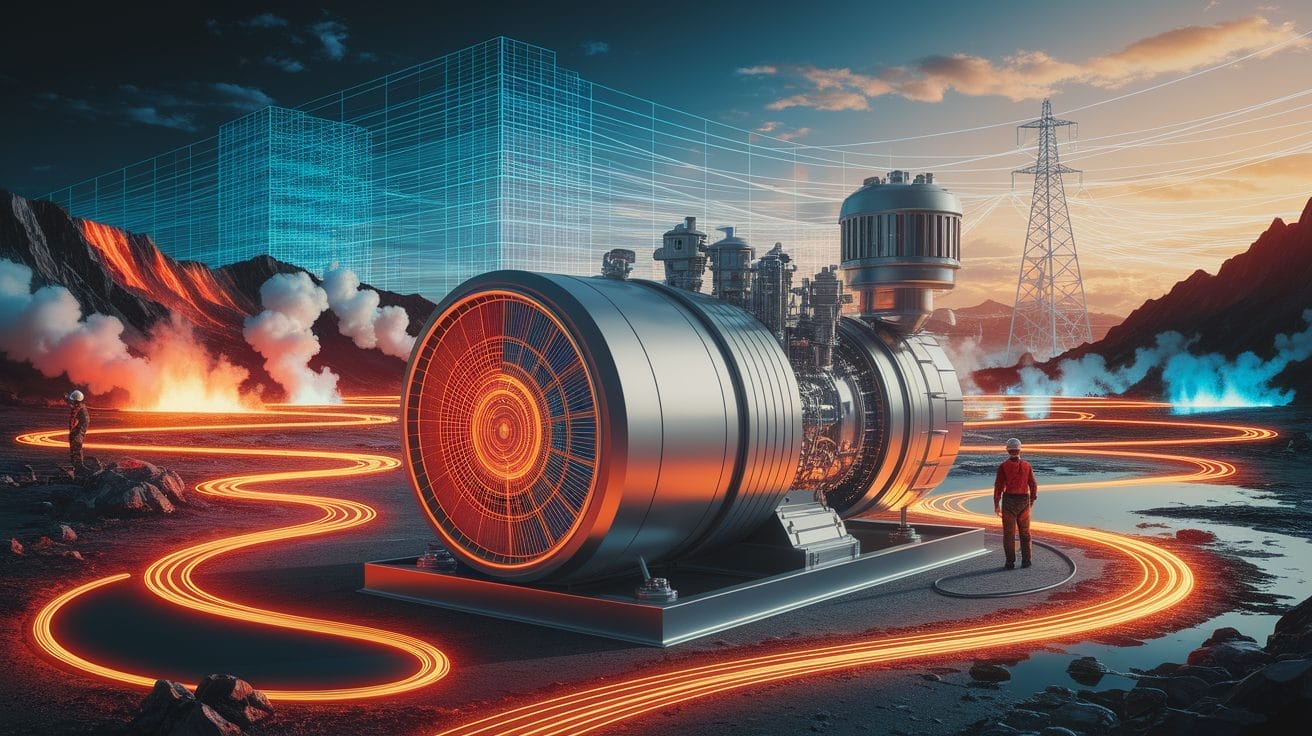

Imagine tapping into the warmth from a campfire, an engine, or even the Sun, and turning it straight into usable electricity—like magic, but based on science! That’s exactly what a thermoelectric generator (TEG) does. It’s a solid-state device that converts heat energy into electrical energy using clever material properties. No spinning turbines, no complex mechanisms—just a temperature difference powering your devices with quiet efficiency.

The Science Behind Thermoelectric Generation

The core principle behind a TEG is the Seebeck effect, discovered in the 19th century. When certain thermoelectric materials have one side heated (the “hot side”) and the other cooled (the “cold side”), charge carriers—electrons or “holes”—travel from the hot to the cold region. This movement creates a voltage difference, and the voltage can drive electrical current through a circuit.

- While the Seebeck effect powers generation, related phenomena such as the Peltier effect involve heat being absorbed or released when current flows through the material.

- The key here is direct thermal-to-electrical conversion—no intermediate mechanical step, unlike traditional heat engines.

- The p-type and n-type semiconductors inside a TEG are wired in series electrically but placed in parallel thermally. This optimizes voltage output while sustaining the temperature gradient.

Key Components and Design

A typical thermoelectric module consists of:

- Semiconductor legs: Usually made from materials like bismuth telluride, lead telluride, or silicon-germanium alloys, which have the right balance of electrical conductivity and low thermal conductivity.

- Ceramic plates: They sandwich the semiconductor legs, providing electrical insulation and mechanical support.

- Hot and cold contacts: Ensuring strong thermal contact with the heat source and the heat sink.

Design choices aim to maximize the difference in temperature between the hot and cold sides while minimizing unwanted heat flow. This balance depends on leg geometry: longer legs reduce heat loss, but increase electrical resistance. Material properties are often summarized by a metric called the figure of merit or ZT value, which combines electrical conductivity, thermal conductivity, and Seebeck coefficient into a single efficiency measure.

Optimizing Performance

Thermoelectric efficiency often hovers between 5–8%, so careful engineering is essential:

- Maintaining a high temperature gradient: The cooler the cold side stays, the more voltage you get.

- Reducing thermal conductivity: Limits unwanted heat transfer across the device.

- Improving electrical conductivity: Helps carriers flow with minimal resistance.

- Using advanced materials and alloys: Researchers are chasing materials with better ZT values for higher performance.

- Optimizing leg geometry: Balancing thermal and electrical pathways for maximum output.

Losses can occur from internal resistance (ohmic heating) and imperfect thermal contacts—but clever design and precise machining can mitigate these issues.

Real-World Applications

You can find TEGs quietly doing their job in places where other power systems struggle:

- Space exploration: NASA spacecraft like Voyager and Mars rovers use radioisotope TEGs for long-lasting, maintenance-free power.

- Automotive waste heat recovery: Turning exhaust heat directly into extra electricity for systems onboard.

- Remote sensing: Powering equipment in far-flung, harsh environments without frequent servicing.

- Portable generators: Ideal for camping or emergency situations where solar panels aren’t practical.

- Industrial waste heat harvesting: Capturing energy from factory processes to feed back into the grid.

Their advantages include solid-state reliability (no moving parts to break), silent operation, and the ability to use any heat source—making them versatile for global energy needs. Learn more about these benefits from this overview of thermoelectric technology.

Beyond the Heat – The Future of Thermoelectric Power

Researchers are exploring new frontiers for TEGs, from nanostructured materials that manipulate phonon and electron transport, to hybrid systems combining thermoelectrics with solar or other renewables. Improvements in ZT values and cost-effective manufacturing could make them far more competitive with conventional generators—and even rival certain solar applications where heat sources are abundant.

As industries focus on energy harvesting and sustainability, thermoelectric generators could become an essential part of the toolkit for tapping into the vast reservoir of waste heat that currently goes unused.