Quick Answer: An internal combustion engine burns fuel inside a chamber to create high-pressure gases that push pistons, turning a crankshaft and ultimately powering a vehicle. Most car engines use a four-stroke cycle — intake, compression, power, exhaust — to keep the process running smoothly. Both gasoline and diesel engines follow this principle but differ in how they ignite the fuel.

Engine Essentials Unveiled

An internal combustion engine (ICE) is essentially a compact power plant. Fuel burns inside a combustion chamber, creating hot, expanding gases that do mechanical work. Unlike external combustion engines (such as steam engines), all the action in an ICE happens right inside its own cylinders.

Here’s why it’s so clever:

- The piston moves up and down inside the cylinder, compressing and expanding space.

- A connecting rod links each piston to the crankshaft, turning straight-line movement into rotation.

- Valves, guided by a camshaft, open and close at precise moments to let in the air-fuel mixture and push out exhaust gases.

- Ignition systems — whether via spark plugs in gasoline engines or heat from compression in diesels — set the combustion process in motion.

Because this all happens in rapid, repeating strokes, the result is continuous, smooth power output.

The Four-Stroke Power Cycle

Most modern engines use the four-stroke cycle. Think of it like a repeating four-step dance:

- Intake stroke: The piston moves down, the intake valve opens, and a fuel-air mixture flows into the combustion chamber.

- Compression stroke: Both valves close, the piston moves up, squeezing the mixture to raise its pressure and temperature.

- Power stroke: At the top, a spark plug (in SI engines) ignites the mixture, causing a burst of high-pressure gas that pushes the piston down with force.

- Exhaust stroke: The exhaust valve opens, the piston rises again, pushing out spent gases through the exhaust system.

This entire process takes two full turns of the crankshaft for each full cycle, delivering steady power to the wheels via the transmission.

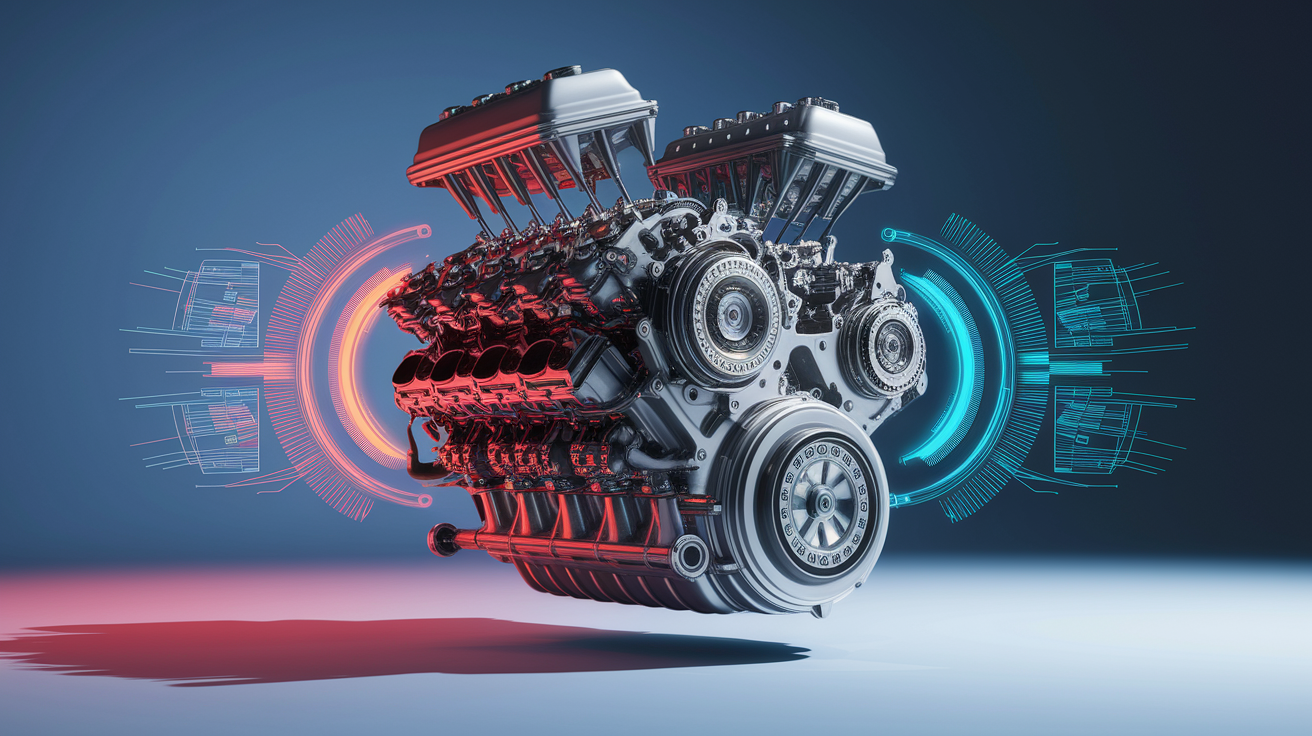

Core Components Driving the Process

Every part of the engine plays a special role in turning explosions into movement. Here’s a breakdown of important pieces, based on illustrated engine diagrams and videos:

- Engine block: The sturdy home for the cylinders.

- Piston: Moves up and down within the cylinder chamber.

- Connecting rod: Transfers piston motion to the crankshaft.

- Crankshaft: Converts reciprocating piston motion into rotational power.

- Camshaft: Controls when valves open and close.

- Valves: Intake valves let the mixture in; exhaust valves let gases out.

- Spark plug: Ignites the air-fuel mix in gasoline engines.

- Fuel injection system: Delivers precise amounts of fuel for combustion.

- Cooling system: Prevents overheating using coolant channels within the engine block.

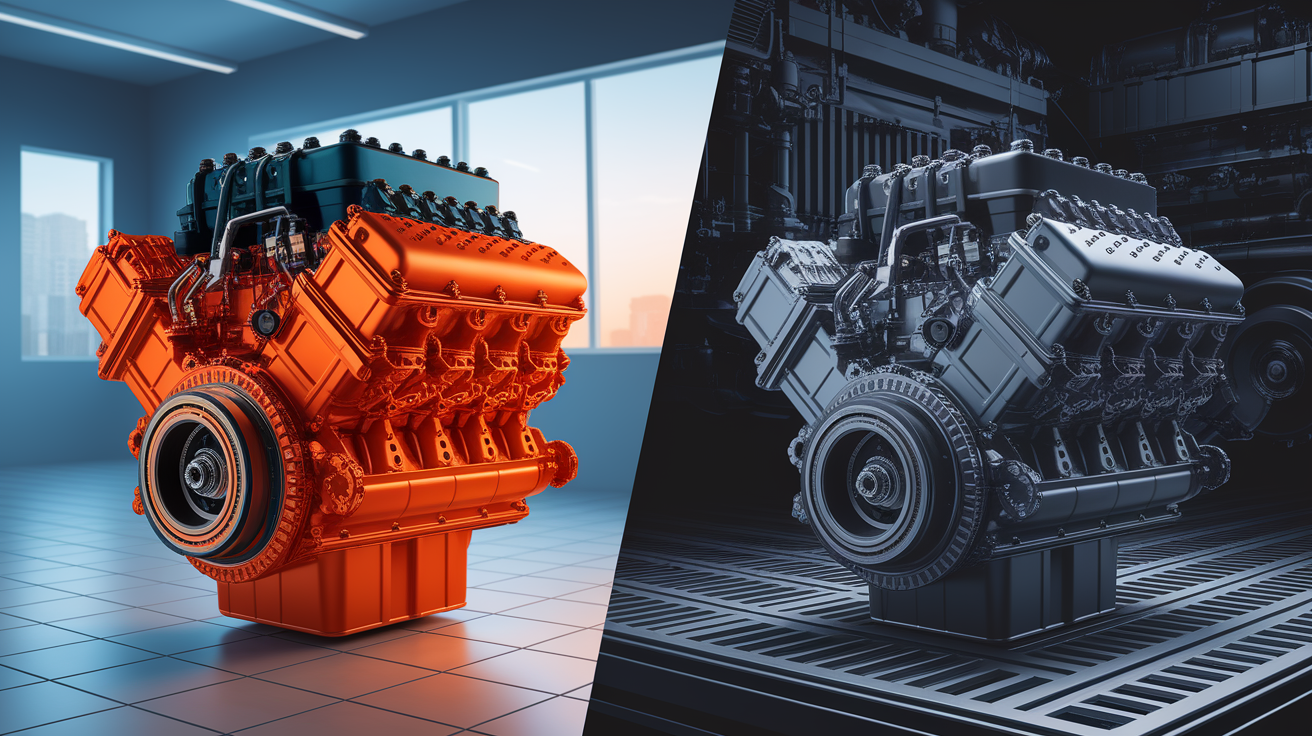

Spark vs Compression Ignition Engines

Internal combustion engines come in different types, but the big divide is between spark ignition (SI) and compression ignition (CI) designs:

- Gasoline (Spark Ignition) Engines: Use a spark plug to ignite a pre-mixed fuel-air charge. Common in most cars due to smooth operation and high RPM capability.

- Diesel (Compression Ignition) Engines: Compress only air until it’s hot enough, then inject diesel fuel directly into the cylinder for spontaneous ignition. Favored for trucks and heavy-duty machines because of strong torque and efficiency.

The difference lies in how the combustion starts, which affects power, efficiency, and even the sound of the engine.

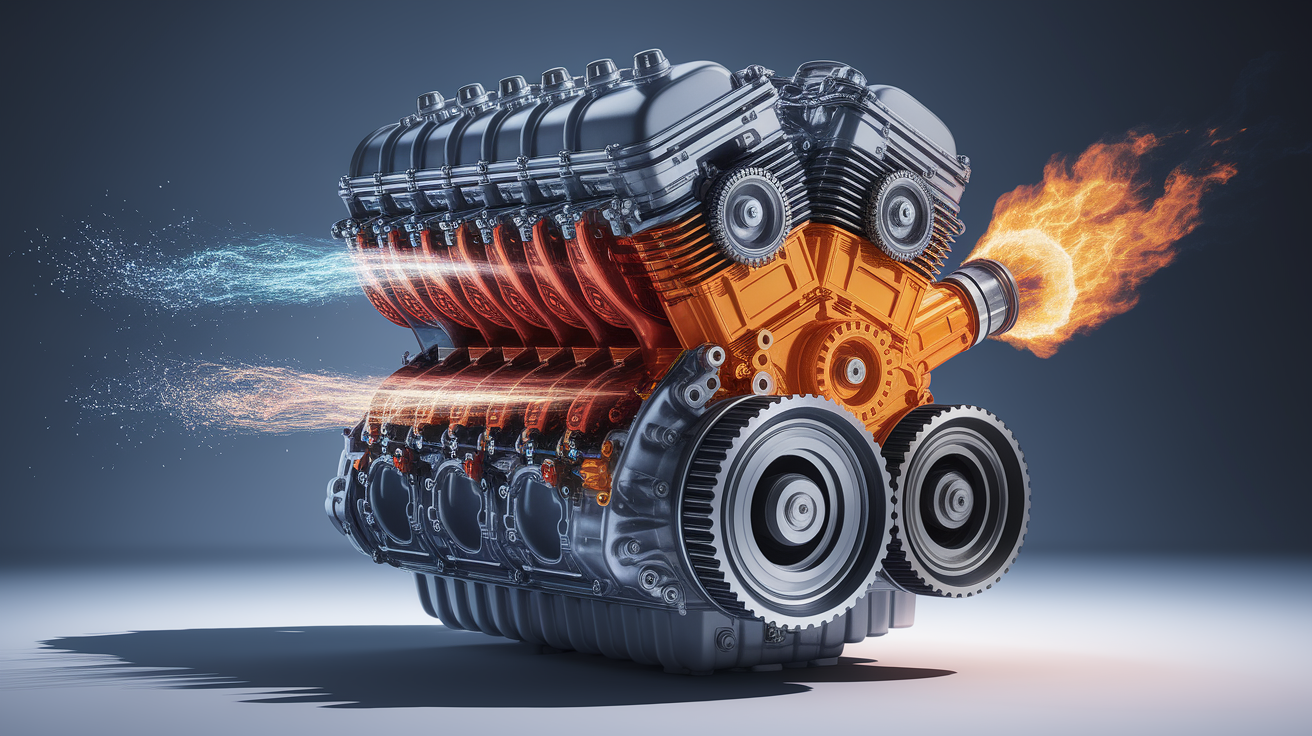

From Heat to Motion: The Thermodynamic Cycle

At its heart, an ICE is a heat engine using thermodynamics to turn thermal energy into work. Gasoline units mainly follow the Otto cycle, and diesels use the Diesel cycle.

Here’s what that means in plain terms:

- Otto cycle: Heat is added while the piston is fixed at the top, then expanding gases push it down.

- Diesel cycle: Heat is added while the piston is moving down during expansion, maintaining constant pressure for part of the stroke.

Efficiency in both depends on factors like compression ratio, fuel quality, and minimizing heat loss. Innovations such as turbocharging, direct fuel injection, and variable valve timing help engines produce more power from less fuel.

Revving Ahead: Wrapping Up

The internal combustion engine is a marvel of moving parts and timed explosions, converting chemical energy into the kinetic energy that powers our vehicles. Whether a gasoline engine firing from a spark plug or a diesel relying on high compression, the principle is the same: control the combustion process so precisely that it delivers smooth, reliable motion. With ongoing improvements in engine performance, cooling systems, and fuel delivery, the ICE continues to play a central role in how we get from one place to another.